Authentically American

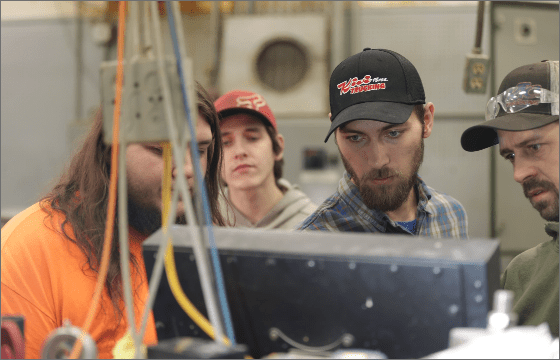

GatorBar is proudly made in Michigan’s Upper Peninsula. Every piece and process behind GatorBar is American made.

Redefining Rebar

In 2013 GatorBar founders Erik Kiilunen and Ken Keranen saw an opportunity to use manufacturing and material science technologies to produce FRP rebar that was cost competitive with steel. The resulting prototypes increased manufacturing speeds by over 1200%... and GatorBar was born.

Since then the GatorBar team—located in Michigan's Upper Peninsula—has continued to use innovative methods to produce the best bar and remain cost competitive with steel and FRP rebar counterparts.

Reinforcing America's Future

2013:

Neuvokas Corp was founded in 2013 by Erik Kiilunen and Ken Keranen from a simple observation: advances in manufacturing and material sciences would allow composite rebar to be produced competitively with its steel counterpart at higher levels of performance.

2014:

In 2014, our proof of concept was validated, our initial mill completed, and our seed investment was obtained.

2015:

We achieved 75 feet per minute for production.

2016:

First truckload sales of GatorBar.

2017:

GatorBar achieved production speeds of 150 feet per minute.

2018:

GatorBar was awarded its second patent and sales surpassed 30 million feet.

2019:

The Department of Energy ARPA grant was awarded to GatorBar and GatorBar sales since inception surpassed 30,000,000 feet.

2020:

GatorBar transitioned from basalt to glass fiber while increasing tensile strength and lowering product costs. We expanded product offerings to include #4 bar and achieved production speeds of 250 feet per minute.

2021:

GatorBar was awarded its third patent and obtained the construction industry's first ICC certification for composite rebar.

2022:

GatorBar achieved 225,000,000 feet of installed product since inception. We obtained membership within NEx: An ACI Center of Excellence for Nonmetallic Building Materials. GatorBar also expanded outside of the Midwest via distributor representation in all 50 states and a nationwide network of sales professionals.

2023:

GatorBar continues to make improvements to the product line-up with the introduction of Grip Technology with zero slivers and better bond.

Affiliations

GatorBar is committed to continual technological advancements as they capitalize on their advantages in price, weight, and strength. Our involvement in various organizations helps us keep a pulse on market trends and make GatorBar the best bar in existence.

- NEx

- National Science Foundation

- Michigan Economic Development Corporation

- Michigan Small Business Development Center

- Keweenaw Chamber of Commerce

- Keweenaw Economic Development Alliance

- Houston Contractors Association

- American Society of Civil Engineers (ASCE)

- Structural Engineers of Texas (SEoT)

- American Society of Indian Engineers

- Purchasing Cooperative of America

- Foundation Performance Association

- BayTran–Bay Area Houston Transportation Partnership

- AIA Continuing Education Provider